Context

The development of new high value-added technologies has significantly accelerated and diversified the global consumption of metallic mineral resources in recent decades. The number of metals used in industry has doubled since the beginning of the twentieth century. Some twenty new elements have now become indispensable for many applications including the production of carbon-free energy, energy storage, computing, telecommunications and aeronautics.

Europe is dependent on its supplies of metallic raw materials, and is now vulnerable to price volatility and the risk of scarcity for some metals. As such, the European Commission has published and regularly updates a list of so-called “strategic” metals, some of which are present in WEEE.

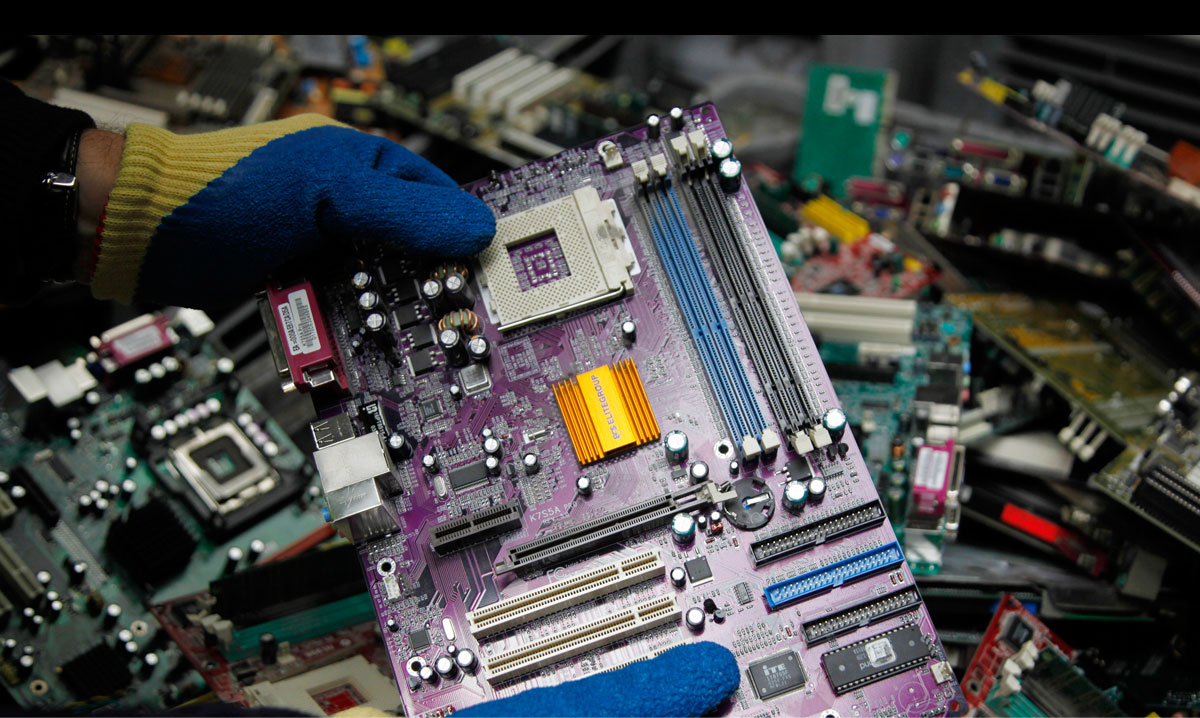

The Urban Mines Chair wants to contribute to the optimization of the recycling of strategic metals contained in the WEEE, which constitutes a complex, dispersed and heterogeneous deposit, the quality and quantity of which evolve in line with the technological advances.

The Chair’s research program

The Chair’s research program on the recycling of strategic metals is divided into four sections:

Teams involved

Team Matériaux, Interfaces et Matière Molle – Institut de Recherche de Chimie Paris – Paris (France)

Team Procédés, Plasmas, Microsystèmes – Institut de Recherche de Chimie Paris – Paris (France)

Team Métallurgie Structurale – Institut de Recherche de Chimie Paris – Paris (France)

Team Synthèse, Electrochimie, Imagerie et Systèmes Analytiques pour le Diagnostic – Institut de chimie pour les sciences de la vie et de la santé – Paris (France)

Expertises

All of the teams involved are a multidisciplinary association between physicochemical process specialists, materials chemists, colloid physicochemists and analytical scientists who share their skills at the interface of materials and processes. . It is able to propose innovative solutions likely to remove the technological locks encountered by the industry in the field of raw materials and energy: nuclear power cycle (uranium mining, chemistry of heat transfer circuits, to waste management), raw material life cycle (hydrometallurgy, bioleaching, elaboration, recycling and remanufacturing), electrochemical energy storage (electrode materials for batteries, supercapacitors, redox flow and electrolytes for lithium-ion batteries), process analysis and monitoring.

Equipments

References

Collet, A. Chagnes, B. Courtaud, J. Thiry, G. Cote, Solvent Extraction of Uranium from Acidic Sulfate Media by Alamine®336: Computer Simulation and Optimization of the Flowsheets, Journal of Chemical Technology and Biotechnology, 84, 1331-1337 (2009).

Chagnes, M-N. Rager, B. Courtaud, J. Thiry, G. Cote, Speciation of vanadium (V) extracted from acidic sulfate media by trioctylamine in n-dodecane modified with 1-tridecanol, Hydrometallurgy, 104, 20-24 (2010).

Chagnes, C. Fossé, B. Courtaud, J. Thiry, G. Cote, Chemical degradation of the mixture of trioctylamine (extractant) and 1-tridecanol (phase modifier) in acidic sulfate media in the presence of vanadium (V), Hydrometallurgy, 105 (3-4), 328-333 (2011).

Beltrami, G. Cote, H. Mokhtari, B. Courtaud, A. Chagnes, Modelling of the extraction of uranium (VI) from concentrated phosphoric acid by synergistic mixtures of bis-(2-ethylhexyl)-phosphoric acid and tri-n-octylphosphine oxide, Hydrometallurgy, 129-130, 118-125 (2012).

Cholico-Gonzalez, M. Avila-Rodrigues, G. Cote, A. Chagnes, Chemical properties of trihexyl(tetradecyl)phosphonium chloride and bis(2,4,4-trimethylpentyl)phosphinic acid mixtures : interactions study by FT-IR and NM spectroscopies », Journal of Molecular Liquids, 187, 165-170 (2013).

Pospiech, A. Chagnes, Highly selective extraction of Zn(II) and Cu(II) from aqueous chloride solutions by mixture of Cyanex 272 and Aliquat 336, Separation Science and Technology, 50 (9), 1302-1309.

Beltrami, G. Cote, H. Mokhtari, B. Courtaud, B. A. Moyer, A. Chagnes, A review on the recovery of uranium(VI) from wet phosphoric acid by solvent extraction processes, Chemical Reviews, 114 (24), 12002–12023 (2014).

J-P. Deblonde, A. Moncomble, G. Cote, S. Bélair, A. Chagnes, Experimental and computational exploration of the UV-visible properties of hexaniobate and hexatantalate ions, RSC Advances, 5, 7619-7627 (2015).

Sun, JY Zhang, M. Marteleur, C. Brozek, EF. Rauch, M. Veron, P. Vernaut, PJ. Jacques, F. Prima, “A new titanium alloy with a combinaison of high strength, high strain hardening and improved ductility”, Scripta Materiala, 94 17-20 (2015).

Manzoni, A. Denquin, P. Vermaut, IP. Orench, F. Prima, RA. Portier, “Shape memory deformation mechanisms of Ru-Nb and Ru-Ta shape memory alloys with transformation temperatures”, Intermetallics, 52, 57-63 (2014).

Elma, F. Prima, T. Gloriant, B. Bolle, Y. Zhong, E. Patoor, R. Laheurte, “Effects of thermomechanical process on the microstructure and mechanical properties of a fully martensitic titanium-based biomedical alloy”, Journal of the mechanical behavior of biomedical materials, 18, 47-56 (2013).

Bacos, F. Rousseau, D. Morvan, “Forming an oxide layer on a component made of a permeable material or a stack material, comprises coating a carrier gas loaded with droplets of at least one precursor of the oxide in a low pressure plasma with component to be coated”, Patent number WO2015082819-A1 (2015).

MA, F. Rousseau, F. Donsanti, D. Lincot, D. Morvan, “Deposition of ZnO thin films from aqueous solution in a low power plasma reactor”, Surface and coating technology, 276, 186-194 (2015).

Rousseau, C. Fourmond, F. Prima, MHV. Serif, O. Lavigne, D. Morvan, P. Chereau, “Deposition of thick and 50% porous YpSZ layer by spraying nitrate solution in a low pressure plasma reactor”, Surface and Coatings technology, 206 (7), 1621-1627 (2011).

Rousseau, S. Awamat, D. Morvan, “A flexible low pressure plasma process for the deposition of complex thick oxide coatings”, High Temperature Material Processes, 13 (3-4), 381-398 (2009).

Rousseau, M. Nikravech, S. Awamat, D. Morvan, J. Amouroux, “Optical emission spectroscopy of a supersonic low-pressure plasma reactor used to synthesis SOFC cathodes thin layer”, High Temperature Material Processes, 10 (3), 431-444 (2006).

Ladner, F. d’Orlyé, C. Perréard, B. Da Silva, C. Guyon, M. Tatoulian, S. Griveau, F. Bedioui, A. Varenne, Surface functionalization of COC microfluidic materials by plasma and click chemistry processes. Plasma Process. Polym., 10 (11), 959–969 (2013).

Ladner, F. d’Orlyé, C. Perréard, B. Da Silva, C. Guyon, M. Tatoulian, S. Griveau, F. Bedioui, A. Varenne, Surface Functionalization by Plasma Treatment and Click Chemistry of a New Family of Fluorinated Polymeric Materials for Microfluidic Chips. Plasma Processes and polymers, 11 (6), 518–523 (2014).