Bioleaching of printed circuit board

A. HUBEAU¹², A. CHAGNES¹, A.G. GUEZENNEC², M. MINIER¹

¹ Chimie ParisTech, PSL Research University, CNRS, Institut de Recherche de Chimie Paris, Paris, France

² Bureau de Recherches Géologiques et Minières, Orléans, France

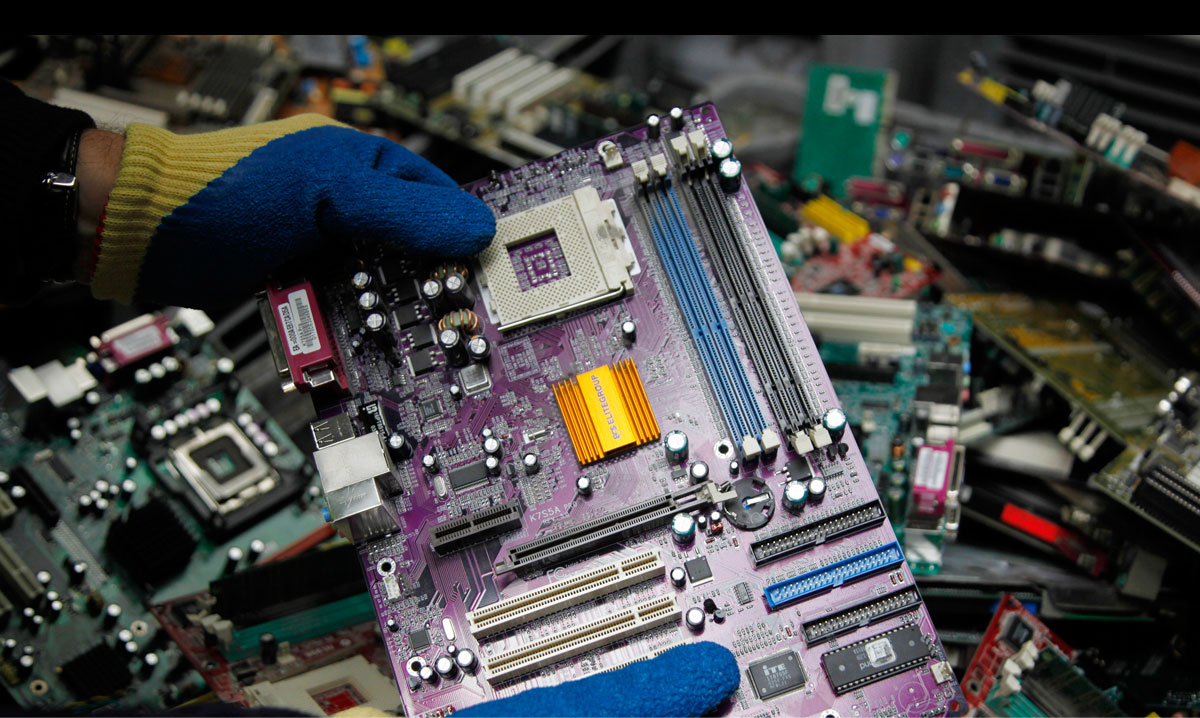

Given its compositions and the huge amounts produced every year, Waste Electrical and Electronic Equipment is a valuable resource. Printed Circuit Boards (PCBs) contain many base metals, as well as strategic and precious ones. Today, the recovery of such metals is based on pyrometallurgy. However, this method presents several disadvantages (including high-energy consumption, toxic gas emissions, etc.). It is therefore necessary to develop new processes to overcome these limitations. Among the alternative technologies, bioleaching, i.e. microorganisms-assisted dissolution, could be combined with other hydrometallurgical techniques to recover metals. Our study aimed at determining and optimizing the dissolution rates of different metals from spent PCBs using an iron-oxidizing acidophilic culture.

The variability of spent PCBs makes it difficult to have reproducible and representative samples from a large initial batch. A methodology of preparation, sampling and characterization was developed to obtain representative samples. The variability of the metal concentration between samples was determined and this protocol was validated.

To reduce the toxicity of metals contained in PCBs towards bacteria, a double-stage reactor has been established. Such bioreactor enables to separate the growth of microorganisms, resulting from the bio-oxidation of Fe(II), from the bioleaching of the samples of ground PCBs, previously characterized. These two steps were studied in batch and continuous mode under different operating conditions. In the first stage, Fe(III) precipitation phenomena were highlighted, which enabled to determine operating conditions that allows the production of leaching solution with stable characteristics over time. In the second stage, the results showed an adaptation of the bacterial culture over time, which enables to reach high dissolution rates for different PCBs concentrations. With 1%(w/v) of solid concentration, the dissolution yields reach 96% for Cu, 85% for Zn, 73% for Ni and 93% for Co. These results pave the way to new perspectives regarding the use of bioleaching for the recovery of some metals from e-wastes.

Plasma Enhanced Recovery of Strategic Elements

J. CRAMER, O. LESAGE, F. PRIMA, D. MORVAN, F. ROUSSEAU

Chimie ParisTech, PSL Research University, CNRS, Institut de Recherche de Chimie Paris, Paris, France

PERSE Project (Plasma Enhanced Recovery of Strategic Elements) : The technological revolution of recent decades has profoundly reshaped society and electronic devices are now widely used throughout the world. The production of primary resources sometimes strives to meet the growing demand for electronic devices, and to demonstrate industrial responsiveness. New recycling processes are therefore needed to address this supply risk. The aim of this project is to study the potential offered by the plasma medium in order to selectively extract critical elements contained in a metal matrix made from electronic waste. Thus, an experimental study was conducted on matrices of typical “printed circuit board” compositions to show the contribution of plasma for elementary pyrometallurgical extraction operations. In parallel, a theoretical study using simulation tools increased the level of understanding in order to optimize the process. By combining these two approaches, it was possible to process CuSn26wt%. binary matrices under oxidizing atmosphere to extract Sn with high selectivity (>90%). An extraction mechanism to calculate kinetic parameters has also been proposed. Indium could also be extracted from CuSn26wt%. + In matrices (150 ppm.) and recovered with a concentration enrichment factor ranging from 30 to 400. Finally, tantalum capacitors were pyrolyzed and thermochemically treated by the plasma in order to recover tantalum at high purity (>99%) in a dry process.

Development of an innovative lab-on-chip for the capture of strategic metals in highly diluted media for analysis and recycling¹

J. GOUYON, S. GRIVEAU, F. D’ORLYE, F. BEDIOUI, A. VARENNE

Chimie ParisTech, PSL Research University, CNRS, Institut de Chimie pour les Sciences de la Vie et de la Santé, Paris, France

Analytical sciences are increasingly connected to sustainable production goals through two main approaches : characterizing products and processes before and after recycling, and developing new green analytical methodologies for recovery. In the field of metals, there exist different methods of analysis before and after recycling with conventional technologies (ICP-AES, ICP-OES, XRD, X-ray fluorescence). In this project, we propose to make an innovative contribution in this field by developing a lab-on-a-chip that can integrate the treatment and analysis of diluted metal solutions. With a view to a specific and sensitive detection, the integrated processing of the sample will capture these metals from the matrix, exploiting the dynamic phenomenon of metal trace confinement in a defined zone of the microchannel. This system should allow species to be concentrated in very small volumes. This capture phenomenon may also be used to consider the recycling of these traces. Thus, the metal containment / release process can be repeated continuously for on-site analysis, remediation of solutions and capture of these metals for recycling / recovery.

¹ co-funded by ADEME